Services

ENVIRONMENTAL

COMPLIANCE STRATEGY

Compliance with water intake and discharge regulations at industrial facilities can be complicated. Developing effective compliance strategies typically relies on many technical disciplines. TWB is experienced in developing scientifically defensible compliance strategies and coordinating their execution. Areas of special focus include the Desalination Amendment to the California Ocean Plan and Section 316(b) of the Clean Water Act.

FISH PROTECTION RESEARCH

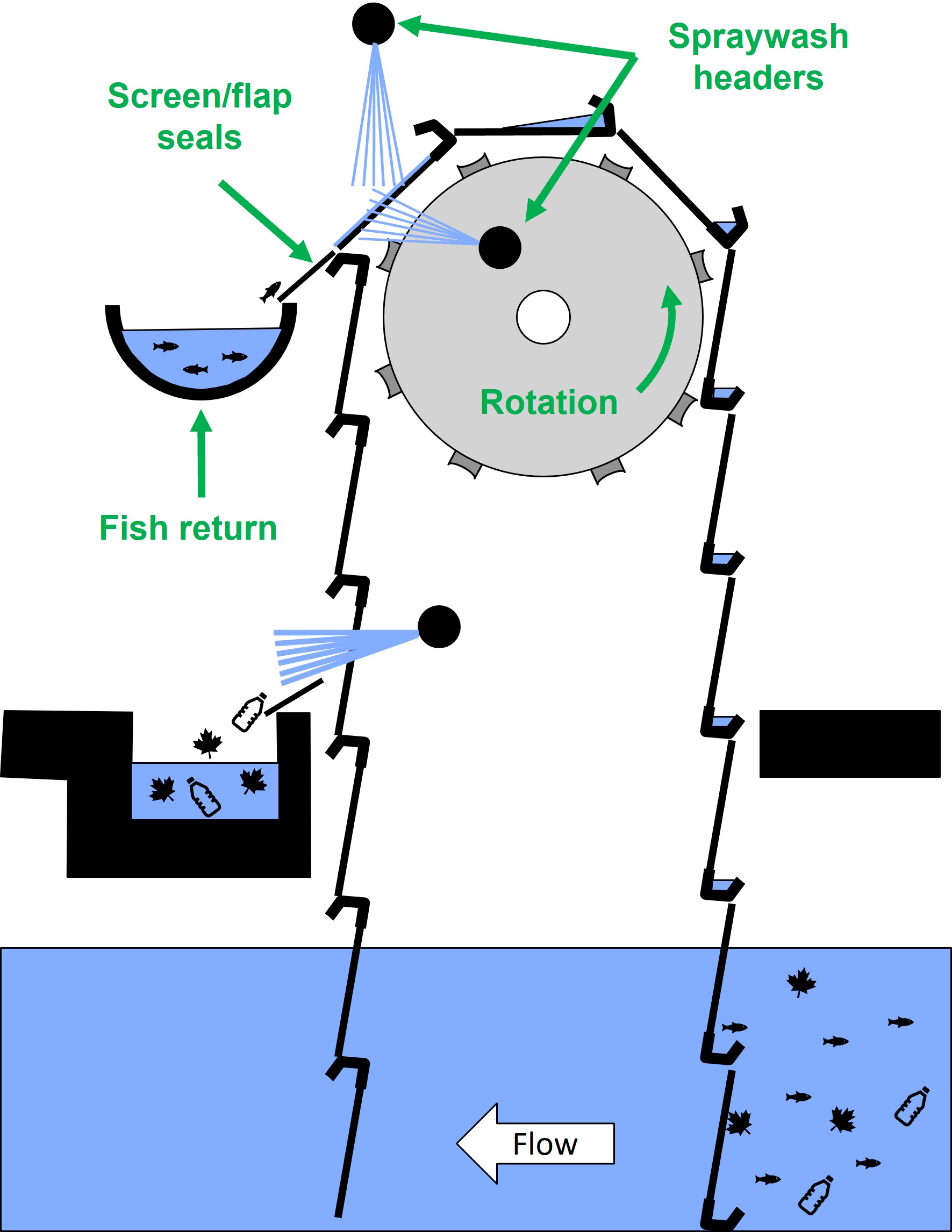

The protection of fish and other aquatic life at large industrial water intakes typically forms the basis of environmental regulation. Intake screening for fish protection has achieved many advances over the years. TWB has been participated in some of this development and tracked the state-of-the-art in fish protection technologies for 25 years. TWB has completed desktop, laboratory, and field research on various fish protection technologies. Our expertise makes us well-positioned to identify and apply the latest intake screening technologies for meeting environmental requirements.

FEASIBILITY ANALYSIS

Feasibility analysis is a critical step in identifying project designs that will minimize impacts, such as impingement and entrainment, to aquatic life. Analyzing the feasibility of alternatives also represents a good risk minimization step in the development of new facilities or expansions/modifications of existing facilities. Often times, the bottleneck in project development is the bridge between engineering and regulatory feasibility; adequately vetting the alternatives can help minimize both regulatory delay and engineering risk. TWB has helped clients balance each of the feasibility components, from the technical to the environmental. These projects have focused on intake equipment such as floating booms, trash racks and rakes, cylindrical wedgewire screens, traveling water screens (dual- and center-flow), and fish and debris return systems.

PILOT-SCALE STUDIES

Before implementing new intake screening technologies at a full-scale, pilot-scale testing is a smart risk-reduction step. TWB has overseen large, multi-year pilot projects of intake screening technologies in the seawater desalination and thermal power generation industries. These projects have focused on technologies such as cylindrical wedgewire screens, air bubbles curtains, and remotely operated vehicles.

INTAKE O&M GUIDANCE

The successful operation of large industrial facilities (e.g., power plants, seawater desalination plants, manufacturing facilities) dictates that water intakes provide a sufficient quantity of high-quality water to the downstream processes. Intake operators must carefully consider how to mitigate both chronic and acute challenges to reliable intake operation. These challenges can range from the extreme (e.g., massive inundations of marine debris such as jellyfish and algae) to the seemingly mundane (e.g., preventive control of biofouling through the application of coatings). TWB works with intake operators to identify such O&M risks in an effort to prevent costly plant outages. By leveraging TWB’s global network of experts, technology developers/vendors, and consulting partners, we can provide site-specific solutions to intake-related O&M problems.

EQUIPMENT VENDOR LIAISON

TEAM BUILDING

With a large network of industry leaders and scientific experts, TWB specializes in bringing the right people to the table to respond to opportunities. Using over 20 years of experience, TWB can assist you at any point in the process—from brainstorming and refining project ideas, to staying on top of potential funding sources, to coordinating multi-disciplinary proposal teams, to writing concise, compelling funding proposals, to setting up and managing projects.